Composite Tooling

Putty, Block Foam, Wood, Composites, Metals

Tooling

Proprietary Putty Patterns

- Strong wooden substructure, foam, fiberglass and in-house engineered putty

- Machined to specific tolerances

- Extremely accurate and very fast turn-around at an economical cost

- Easy-to-sand surface can be finished to 80 grit or given a machined primer surface and sanded to a finer finish.

- Male or female shapes are available depending on the application and geometry provided.

- Designed for room temperature applications, but can be modified to withstand temperatures up to 180ºF

- Primer surface option available

- Laser tracking and vacuum integrity options are available

Block Foam Patterns & Wood Patterns

- Machined pattern fabricated out of block foam, MDF or modeling board

- Block foam allows for the maintenance of higher tolerances and can reach higher curing temperatures than the JI proprietary putty patterns

- Medium Density Fiberboard (MDF) wood is stable at higher temperatures than putty, however, the surface finish may be rougher

- MDF is also a suitable material for casting patterns

- Foam patterns can also be provided with a primer finish

- A wide variety of foam materials and densities are available depending on your application

Short Run Molds

Using Janicki’s putty material system, we make short-run molds for one-off or short-production production runs. By shipping in segments and assembling onto a steel frame, there is virtually no limit to the size of the part.

Gel Coat Tooling

Janicki’s Gel Coat tooling is designed with hard, durable, high-gloss surfaces required to produce superior-grade products for marine, transportation and architectural industries. Our Gel Coat molds have a mirror-like finish, that is scratch and craze resistant for producing products with a high-quality finish.

Janicki Gel Coat molds are made of fiber-reinforced composites with low-shrink performance polyester resins using infusion or open-molded processing in a typical thickness of 0.625 inches.

- Fiberglass Facesheet

- 200°F Temp Tooling

- 200+ Part Cycles

- Trussed Steel Frame

- 400 Grit and higher finish

- Resistance to ultraviolet degradation and hydrolysis

- Produce aesthetically appealing parts

- Long-lasting maintenance-free performance

- Protective barrier that increases the life and cycles of the mold

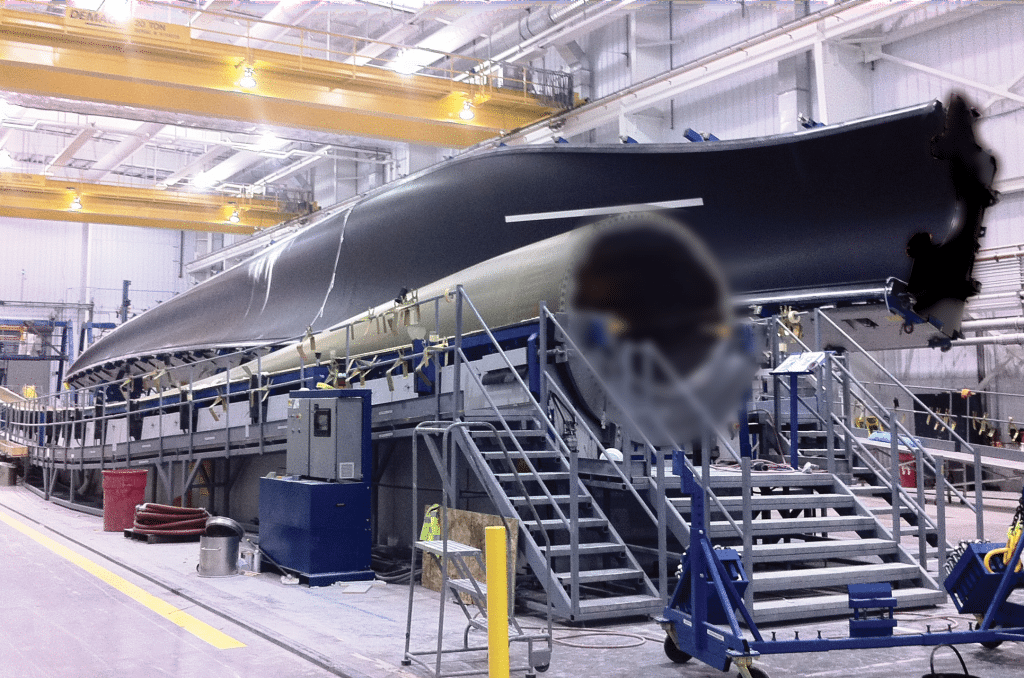

Fiber Reinforced Plastic Tools

Molded from machined patterns; built to customer specifications. Composite consists of varying thickness fiberglass layers, a rigid balsa or foam core, and a durable tooling gel-coat finish. We have engineered FRP mold systems up to 220 feet in length.

250° Composite Tools

Carbon fiber or fiberglass composite tools, surface finishes optional depending on customer needs.

Cast 250° Tool

Also referred to as molded or transfer tools

- Infused on a highly accurate machined pattern

- Use Temperature: 250° F

- Tolerances: up to ± .010″

- Support: Steel tubing or composite egg-crate

Machined 250° Tool

- Machined tools provide higher accuracies than cast

- Includes laser tracking reports and vacuum verification

- Use Temperature: 250° F (modifications can provide a 300° use temperature)

- Tolerances: ± .005″ – .015″

- Support: Steel or composite egg-crate

350° Composite Tools

Our 350° tools are a carbon fiber or fiberglass tool infused with an epoxy resin formulated to customer specifications. These 350° tools are available in two variations: cast and machined. Machined tools allow for the maintenance of higher accuracies. These 350° tools are provided with laser tracking and vacuum verification is performed to ensure conformity.

Cast 350° Tool

Cast 350° tools are infused on a highly accurate machined pattern and produce an accurate tool with optional surface finishes.

- Use Temperature: 350° F

- Tolerances: up to ± .010″

- Support: Composite egg-crate

Machined 350° Tool

Machined 350° tools are infused on a pattern and machined on its support structure with our 5-axis mills.

- Surface is extremely accurate and finished to exact specifications

- Use Temperature: 350° F

- Tolerances: ± .005″ – .015″

- Finish: Machined; 32 rms typical

- Support: Steel or Composite egg-crate